Mechini e Feletseng ea ho Etsa Litapole ka Moralo o Mocha

- Sebaka sa Tšimoloho:

- Shanghai, China

- Lebitso la Brand:

- LITŠOANTŠI

- Nomoro ea Mohlala:

- JP-XF0019

- Mofuta:

- morero o felletseng

- Palo ea li-volts:

- 220V/380V

- Matla:

- 3kw

- Boima ba 'mele:

- 800kg

- Boemo(L*W*H):

- 2100*1460*1590mm

- Setifikeiti:

- CE/ISO9001

- Selemo:

- 2018

- Tiisetso:

- 1 Selemo

- Sebopeho:

- tharollo ea turnkey

- Bokhoni:

- 100kg/h ho isa 10T/H matla a kalafo kamoo moreki a hlokang kateng

- Mosebetsi:

- Mosebetsi o mongata

- Tšebeliso:

- Tšebeliso ea indasteri

- Mmala:

- Litlhoko tsa bareki

- Lisebelisoa tse so ntlafatsoe:

- 304 Tšepe e se nang Sainless

- Ntho:

- mochini o halikiloeng oa litapole

- Matla a Phepelo:

- 20 Set/Sets ka Mochini oa ho lokisa litapole ka Khoeli

- Lintlha tsa Sephutheloana

- Sephutheloana se tsitsitseng sa lehong se sireletsa mochine ho tloha ho otla le ho senyeha.Filimi ea polasetiki ea maqeba e boloka mochine o se na mongobo le ho senya.Sephutheloana se se nang mokelikeli se thusang mokhoa o boreleli oa meetlo.Mochini o moholo oa boholo o tla kenngoa ka setshelo ntle le sephutheloana.

- Boemakepe

- boema-kepe ba Shanghai

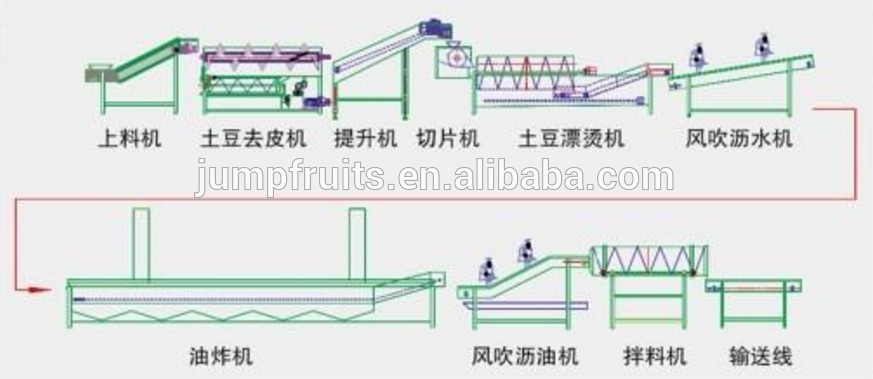

Mohala oa tlhahiso ea litapole:

Ts'ebetso ea ho hlahisa li-fries tsa Frozen:

Enhance — Steam Spray — Cleaning Peeling — Khetha — Cut — Air Bubble Cleaning — Blanching — Dehydration — Mochini oa ho Frying — De-oiling — - Frozen — Packaging — Storage

Lenane la lisebelisoa tsohle tsa mohala ka tsela e latelang:

Mochini oa ho hlatsoa - Mochini oa ho fepa -Mochini oa ho penta -Tlhahlobo ea conveyor-Mochini o phahamisang—-Mochini oa ho roka—-Mochini oa blanching -

Mochini o futhumatsang—Mochini o futhumatsang metsi—Mochini o halikang oli—Mochine o tlotsang oli—Mochine o tlosang oli—-Conveyor—-Tanka ea polokelo ea oli—-Mochini o futhumatsang—-Liphaephe, lipompo le li-valve—-Sebōpi sa ho chesa—-Secheso sa mocheso—Sesebelisuoa sa mocheso

Mochini o moholo oa ho paka o otlolohileng o kopanya (boima ka bohona)

JUMP e boloka boemo ba boetapele ho peista ea tamati le mohala oa ho lokisa lero la apole.Re boetse re fihletse likatleho tse ntle ho lisebelisoa tse ling tsa litholoana le meroho, joalo ka:

1. Mohala oa tlhahiso ea lero bakeng sa lero la lamunu, lero la morara, lero la jujube, seno sa kokonate / lebese la kokonate, lero la kharenate, lero la lehapu, lero la cranberry, lero la perekisi, lero la cantaloupe, lero la papaya, lero la sea buckthorn, lero la lamunu, lero la fragola, mulberry. lero, lero la phaenapole, lero la kiwi, lero la wolfberry, lero la mango, lero la sea buckthorn, lero la litholoana tse sa tloaelehang, lero la rantipole, lero la poone, lero la guava, lero la cranberry, lero la blueberry, RRTJ, lero la loquat le lino tse ling tse tlatsang mohala oa tlhahiso.

2. Na line ea tlhahiso ea lijo bakeng sa perekisi e entsoeng ka makotikoting, li-mushroom, sauce e entsoeng ka makotikoting, peista, arbutus e entsoeng ka makotikoting, lilamunu tse ka makotikoting, liapole, lipere tse entsoeng ka makotikoting, liphaenapole, linaoa tse tala tse entsoeng ka makotikoti, letlobo la bamboo, likomkomere tse entsoeng ka makotikoti, lihoete tse entsoeng ka makotikoting. , cherries e ka makotikoting, ciliegia e entsoeng ka makotikoting

3. Mohala oa tlhahiso ea soso bakeng sa moriana oa mango, sopho ea fragola, moriana oa cranberry, moriana oa makotikoting oa hawthorn joalo-joalo.

Re ithutile mahlale a hloahloa le theknoloji e tsoetseng pele ea enzyme ea baeloji, e sebelisitseng ka katleho mehala e fetang 120 ea jeme ea lapeng le kantle ho naha le lero mme re thusitse bareki ho fumana lihlahisoa tse ntle haholo le melemo e metle ea moruo.

E ikhethang ea rona-Tharollo ea Turnkey.:

Ha ho hlokahale hore u tšoenyehe haeba u tseba hanyenyane ka mokhoa oa ho etsa polante naheng ea heno. Ha re u fe lisebelisoa feela, empa hape re fana ka ts'ebeletso e le 'ngoe feela, ho tsoa ho moralo oa hau oa polokelo (metsi, motlakase, mouoane), koetliso ea basebetsi, ho kenya mochine le ho lokisa liphoso, tšebeletso ea nako e telele ka mor'a ho rekisa joalo-joalo.

Consulting + Conception

E le mohato oa pele le pele ho ts'ebetsong ea morero, re tla u fa litšebeletso tsa boeletsi tse nang le phihlelo e ngata le tse nang le bokhoni bo phahameng.Ho ipapisitsoe le tlhahlobo e batsi le e phethahetseng ea boemo ba hau ba 'nete le litlhoko tsa hau, re tla hlahisa tharollo ea hau e ikhethileng.Ka kutloisiso ea rona, lipuisano tse shebaneng le bareki li bolela hore mehato eohle e reriloeng - ho tloha mohatong oa pele oa kemolo ho fihlela mohatong oa ho qetela oa ts'ebetsong - e tla etsoa ka mokhoa o hlakileng le o utloisisoang.

Moralo oa Morero

Mokhoa oa ho rala merero ea profeshenale ke ntho e hlokahalang bakeng sa ho phethahala ha merero e rarahaneng ea li-automation.Motheong oa mosebetsi o mong le o mong, re bala linako le lisebelisoa, 'me re hlalosa liketsahalo tsa bohlokoa le merero.Ka lebaka la kamano ea rona e haufi le tšebelisano 'moho le uena, maemong ohle a morero, moralo ona o shebaneng le sepheo o netefatsa katleho e atlehileng ea morero oa hau oa matsete.

Moralo + Boenjiniere

Litsebi tsa rona mafapheng a mechatronics, boenjiniere ba taolo, mananeo, le nts'etsopele ea software li sebelisana haufi-ufi mohatong oa nts'etsopele.Ka ts'ehetso ea lisebelisoa tsa ntlafatso ea profeshenale, mehopolo ena e ntlafalitsoeng ka kopanelo e tla fetoleloa ho moralo le meralo ea mosebetsi.

Tlhahiso + Kopano

Mokhahlelong oa tlhahiso, lienjineri tsa rona tse nang le boiphihlelo li tla kenya tšebetsong mehopolo ea rona e ncha ho limela tsa senotlolo.Khokahano e haufi pakeng tsa batsamaisi ba merero ea rona le lihlopha tsa rona tsa kopano e netefatsa liphetho tse sebetsang hantle le tsa boleng bo holimo.Ka mor'a ho phethoa ka katleho ha mohato oa teko, semela se tla neheloa ho uena.

Kopanyo + Ho laela

E le ho fokotsa tšitiso efe kapa efe le libaka tse amanang le tlhahiso le lits'ebetso ho fihlela bonyane, le ho netefatsa tlhophiso e bonolo, ho kengoa ha polante ea hau ho tla etsoa ke lienjiniere le litsebi tsa litšebeletso tse abetsoeng le ho tsamaisana le nts'etsopele ea projeke ka bomong. le mekhahlelo ea tlhahiso.Basebetsi ba rona ba nang le boiphihlelo ba tla etsa bonnete ba hore li-interfaces tsohle tse hlokahalang lia sebetsa, 'me semela sa hau se tla kengoa tšebetsong ka katleho.

Sephutheloana se tsitsitseng sa lehong se sireletsa mochine ho tloha ho otla le ho senyeha.

Filimi ea polasetiki ea maqeba e boloka mochini o tsoa mongobo le ho bola.

Sephutheloana sa mahala sa fumigation se thusa ho hlakola mekhoa e metle.

Mochini o moholo o tla beoa ka har'a setshelo ntle le sephutheloana.