Indasteri Fruit Vegetables Tomate/Blueberry/Strawberry/Hot Pepper/Mango Jam/Paste/Sauce/Puree Production Line

- Boemo:

- E ncha

- Sebaka sa Tšimoloho:

- Shanghai, China

- Nomoro ea Mohlala:

- JP-FPL

- Mofuta:

- pulper

- Palo ea li-volts:

- 220V/380V

- Matla:

- 12000-100000w

- Setifikeiti:

- CE/ISO9001

- Tiisetso:

- 1 Selemo

- Ho fanoe ka Tšebeletso ea Ka mor'a Thekiso:

- Lienjineri tse fumanehang ho sebeletsa mechini mose ho maoatle

- Lebitso la sehlahisoa:

- mola oa tlhahiso ea jeme ea litholoana

- Kopo:

- ho haha semela sa lijo le seno

- Boitsebiso:

- SUS 304 tšepe e sa hloekang

- Bokhoni:

- Lithane tse 20 ho isa ho tse 1500 tsa kalafo ka letsatsi kamoo moreki a hlokang kateng

- Mosebetsi:

- Mosebetsi o mongata

- Tšebeliso:

- Tšebeliso ea indasteri

- Lebitso:

- mochini oa ho etsa jeme oa litholoana

- Sebopeho:

- Tlosa Senotlolo

- Mmala:

- Litlhoko tsa bareki

- Ntho:

- Mochini oa Jam oa Litholoana tsa indasteri

- Matla a Phepelo:

- 50 Set/Sets ka Selemo line ea tlhahiso ea jeme ea blueberry

- Lintlha tsa Sephutheloana

- Sephutheloana se tsitsitseng sa lehong se sireletsa mochine ho tloha ho otla le ho senyeha.Filimi ea polasetiki ea maqeba e boloka mochine o se na mongobo le ho senya.Sephutheloana se se nang mokelikeli se thusang mokhoa o boreleli oa meetlo.Mochini o moholo oa boholo o tla kenngoa ka setshelo ntle le sephutheloana.

- Boemakepe

- boema-kepe ba Shanghai

- Lead time:

- Ka matsatsi a 90

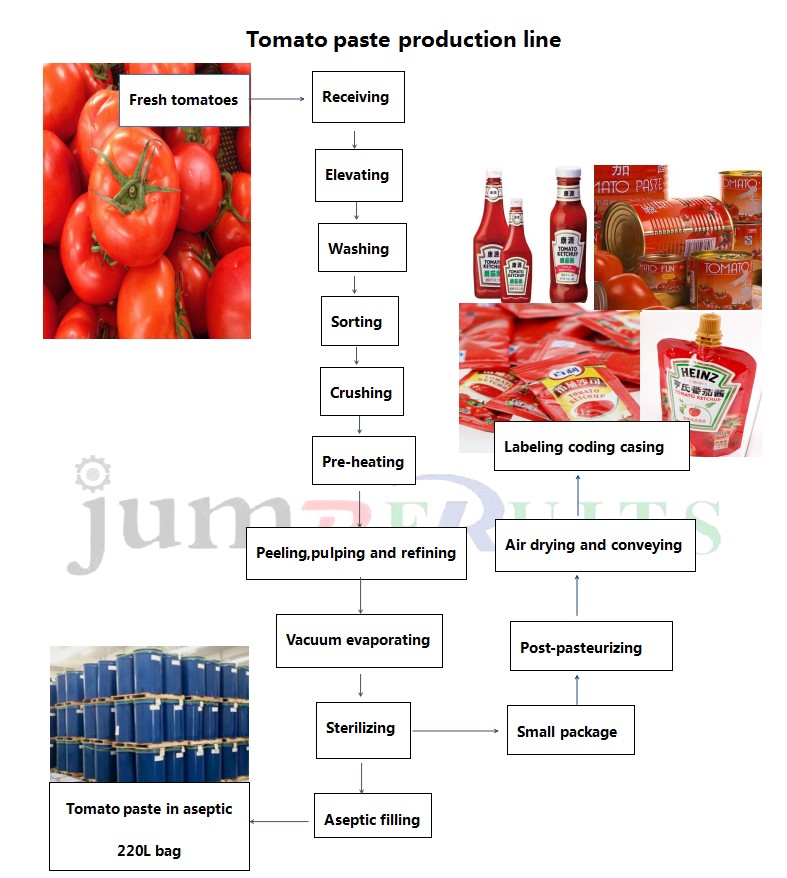

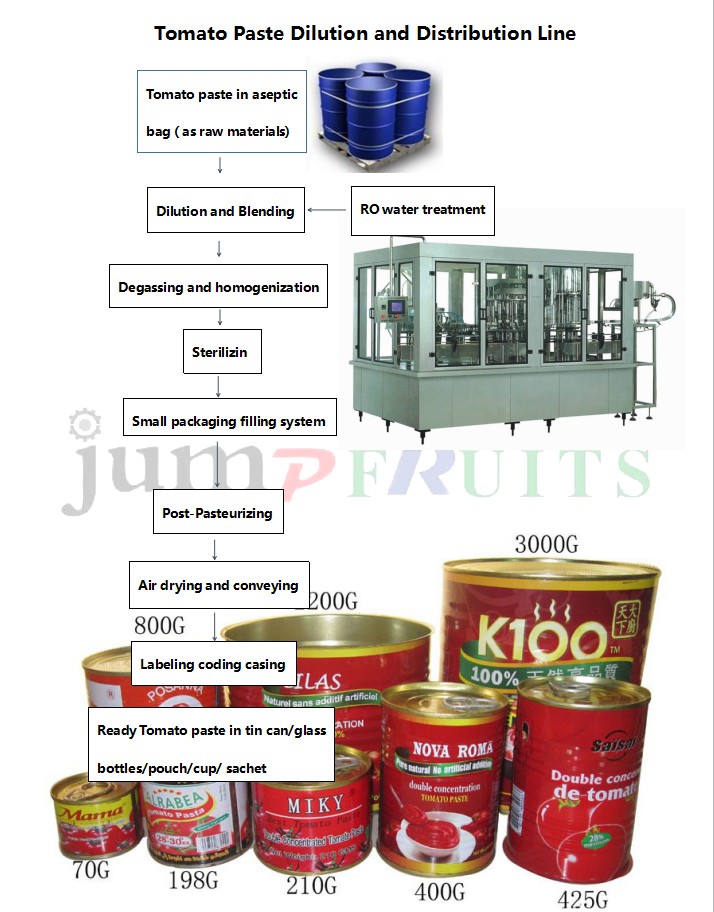

A: Sistimi ea papatso ea litholoana tsa mantlha, sisteme ea ho hloekisa, sistimi ea ho hlopha, sistimi e silakanyang, sistimi ea ho futhumatsa pele ho futhumatsa, sistimi ea pulping, sistimi ea mahloriso ea vacuum, sterilization system, aseptic bag filling system.

B: pompo → moqomo o kopanyang → homogenization → deaerating → mochini o hlapang → mochini o hlatsoang → mochini o tlatsang → mochini o kopanyang → mochini o fafatsang ka kotopo → se omisitsoeng → likhoutu → mabokose

3. Sehlahisoa sa ho qetela sa mahloriso:Brix 28-30%, 30-32% serame se robehileng le mocheso o robehileng, 36-38%

Bakete Elevator

1. sebopeho sa nkho e boreleli khahlanong le litholoana tsa clamping, tse loketseng tamati, fragola, apole, pere, apricot, joalo-joalo.

2. ho matha ka mokhoa o tsitsitseng ka lerata le tlaase, lebelo le fetolehang ka transducer.

3. li-bearings tsa anticorrosive, tiiso ea mahlakoreng a mabeli.

Mochini oa ho Bulula le ho Hlatsoa Moea

1 E sebelisoa ho hlatsoa tamati e ncha, fragola, mango, joalo-joalo.

2 Moralo o ikhethileng oa ho surfing le ho bubble ho netefatsa ho hloekisa le ho fokotsa tšenyo ea litholoana hape.

3 E loketse mefuta e mengata ea litholoana kapa meroho, joalo ka tamati, fragola, apole, mango, joalo-joalo.

Ho ebola, ho phunya le ho Hloekisa Monobloc (Pulper)

1. Sehlopha se ka ebola, sa senya le ho hloekisa litholoana hammoho.

2. Sekhahla sa skrine sa strainer se ka fetoha (fetoha) ho latela tlhoko ea moreki.

3. Theknoloji e kenyelelitsoeng ea Setaliana, thepa ea boleng bo phahameng ba tšepe e sa hloekang e kopanang le thepa ea litholoana.

Belt press extractor

1. E sebelisoa haholo ho hula le ho ntša metsi a mefuta e mengata ea acinus, litholoana tsa pip le meroho.

2. yuniti e amohela theknoloji e tsoetseng pele, khatiso e kholo le ts'ebetso e phahameng, tekanyo e phahameng ea othomathike, e bonolo ho sebetsa le ho e hlokomela.

3. sekhahla sa ho ntšoa e ka ba ho fumana 75-85% (ho ipapisitse le thepa e tala)

4. letsete le tlaase le katleho e phahameng

Preheater

1. Ho koala enzyme le ho sireletsa 'mala oa peista.

2. Taolo ea mocheso oa Auto le mocheso oa ho tsoa lia fetoha.

3. Sebopeho sa li-tubular tse ngata tse nang le sekoahelo sa ho qetela

4. Haeba phello ea preheat le ho tima enzyme e hlōlehile kapa e sa lekana, phallo ea sehlahisoa e khutlela tube hape ka ho toba.

Evaporator

1. Mehaho e ka fetohang le e laolehang ea ho kopana le mocheso o tobileng.

2. Nako e khutšoanyane ka ho fetisisa ea ho lula, ho ba teng ha filimi e tšesaane ho pholletsa le bolelele bohle ba li-tubes ho fokotsa nako le nako ea ho lula.

3. Moralo o khethehileng oa litsamaiso tsa kabo ea metsi ho netefatsa tšireletso e nepahetseng ea li-tube.Phepelo e kena ka holim'a calandria moo mofani oa thepa a netefatsang sebopeho sa filimi ka holim'a bokahare ba tube ka 'ngoe.

4. Phallo ea mouoane e kopane le mokelikeli 'me mouoane o hula o ntlafatsa ho fetisa mocheso.Mouoane le mokelikeli o setseng li arotsoe ka searohanyi sa leholiotsoana.

5. Moralo o sebetsang hantle oa likarohano.

6. Ho hlophisoa ha liphello tse ngata ho fana ka moruo oa mouoane.

Kenya ka har'a sterilizer ea tube

1. Momahano o na le tanka e amohelang sehlahisoa, tanka ea metsi a chesang haholo, lipompo, lihlahisoa tse peli tsa lihlahisoa, li-tubular superheated water generated system, tube in tube heat exchanger, PLC system control, Control cabinet, steam inlet system, valves le sensors, joalo-joalo.

2. Theknoloji ea Italy e kenyelelitsoeng mme e lumellana le Euro-standard

3. Sebaka se seholo sa phapanyetsano ea mocheso, tšebeliso e tlaase ea matla le tlhokomelo e bonolo

4. Adopt seipone welding tech le ho boloka phala e boreleli e kopane

5. Ho khutlela morao haeba ho se na sterilization e lekaneng

6. CIP le auto SIP li fumaneha hammoho le aseptic filler

7. Boemo ba mokelikeli le temp e laoloang ka nako ea sebele