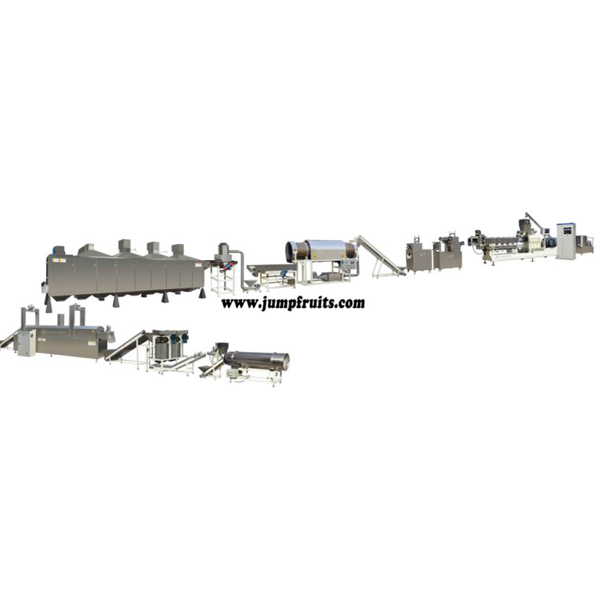

Mochini oa Pasta le Lisebelisoa tsa Spaghetti

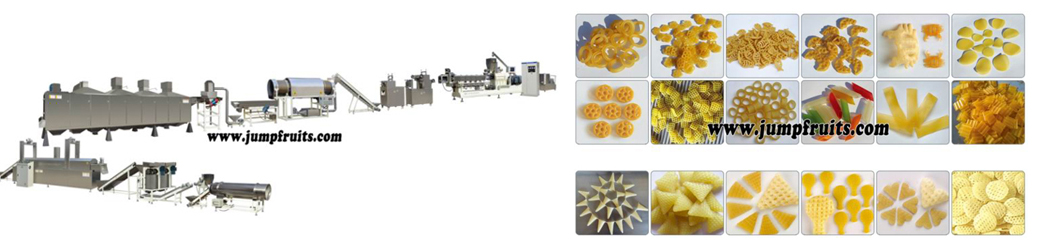

Mohala oa tlhahiso ho tsoa ho lisebelisoa tse tala, ho fana ka thepa e tala, ho bopa extrusion, ho baka ho fihlela sehlahisoa se felileng se ka phethoa ka nako e le 'ngoe.Mohala oa tlhahiso o ka hlahisa mefuta eohle ea pasta, macaroni, li-tubes tse pota-potileng, li-square tubes, matlapa a enamel le lihlahisoa tse ling ho ea ka thepa e thusang.Ho ea ka mefuta e fapaneng ea liforomo le lisebelisoa tse thusang, e ka boela ea hlahisa lijo tse monate tse bobebe joalo ka likotoana tsa crispy le litapole tsa litapole.

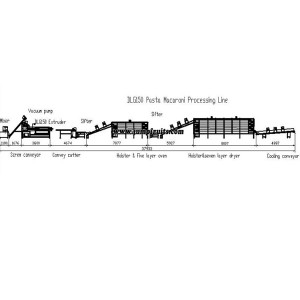

Mochini oa pasta le thepa ea Spaghetti Mokhoa oa ho phalla

Mixer--Screw conveyor—Extruder--Cutter--Flat conveyor--Hoister--Dyer--Hoister--Dryer--Mochini o pholileng--Mochini o pakang

Mochini oa pasta le lisebelisoa tsa Spaghettilikaroloana:

1. Mixer: Ho ea ka mela e fapaneng ea tlhahiso, mefuta e fapaneng ea li-mixer e sebelisoa.

2.Screw conveyor: E sebelisa enjene joalo ka sekontiri sa screw sa motlakase ho netefatsa hore e jara kapele le ha bonolo.

3. Extruder: Ho ea ka mela e fapaneng ea tlhahiso, mefuta e fapaneng ea li-extruder e sebelisoa.Sephetho se ka tloha ho 100kg/h ho ea ho 200kg/h.Phofo ea poone, phofo ea raese, phofo le phofo li ka sebelisoa e le thepa e tala.

4. Mochine o romelang moea: Matla a moea a fene a sebelisetsoa ho fetisetsa thepa e tala ka ontong, 'me ho ka khethoa li-fan tse fapaneng (kapa mechine ea ho phahamisa) ho latela lihlahisoa tse fapaneng.

5. Ovine e nang le mefuta e mengata: ontong hangata ke onto ea motlakase, mocheso o fetoloa pakeng tsa likhato tse 0-200 ka khabinete ea taolo, mokotla o ka hare oa tšepe e sa hloekang habeli, nako ea ho baka e ka fetoloa ho latela lebelo, ho na le likarolo tse tharo, tse hlano. layers, lera tse supileng Setofo sa Stainless steel.