Red Dates Concentrate Juice / Paste Production Line

- Boemo:

- E ncha

- Sebaka sa Tšimoloho:

- Shanghai, China

- Lebitso la Brand:

- OEM

- Nomoro ea Mohlala:

- JPF-ZZ2589

- Mofuta:

- morero oa senotlolo

- Palo ea li-volts:

- 220V/380V

- Matla:

- 2.2kw

- Boima ba 'mele:

- 200kg

- Boemo(L*W*H):

- 1380*1200*2000mm

- Setifikeiti:

- CE ISO

- Tiisetso:

- Lilemo tse 2, Lilemo tse 2

- Ho fanoe ka Tšebeletso ea Ka mor'a Thekiso:

- Lienjineri tse fumanehang ho sebeletsa mechini mose ho maoatle

- Lebitso la sehlahisoa:

- red dates concentrate juice production line

- Mmala:

- Litlhoko tsa bareki

- Kopo:

- Meroho ea Motso

- Boitsebiso:

- Sebetsa 304

- Bokhoni:

- 2-10t/h

- Mosebetsi:

- Mosebetsi o mongata

- Tšebeliso:

- Tšebeliso ea indasteri

- Sebopeho:

- Bokhoni bo Phahameng

- Ntho:

- Morero oa Turnkey

- Matla a Phepelo:

- 10 Set/Sets ka Khoeli

- Lintlha tsa Sephutheloana

- sephutheloana ka lebokoseng

- Boemakepe

- Shanghai

- Lead time:

- ka likhoeli tse 3 kapa ho feta

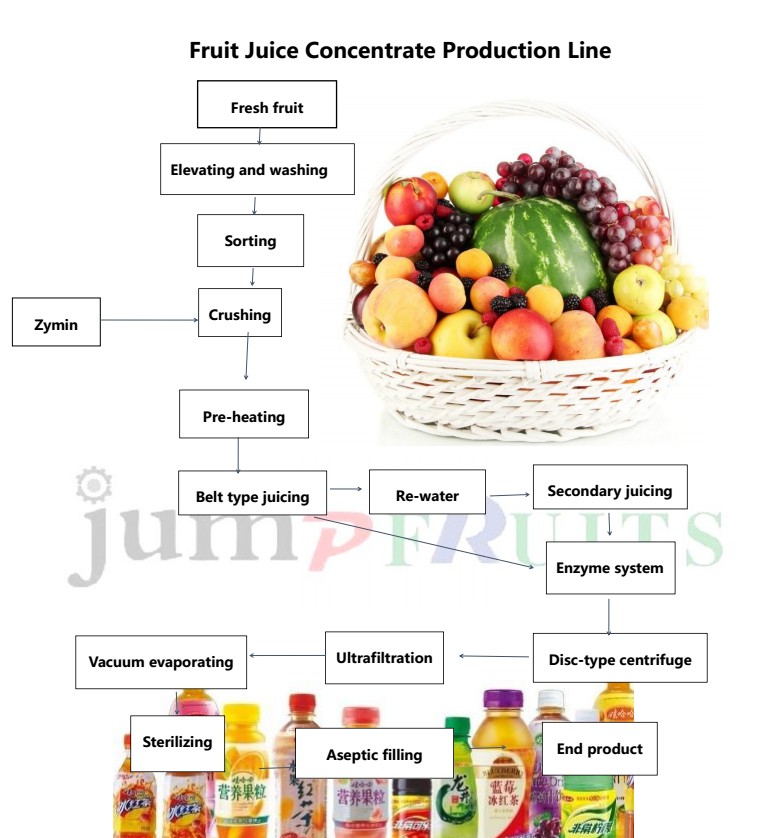

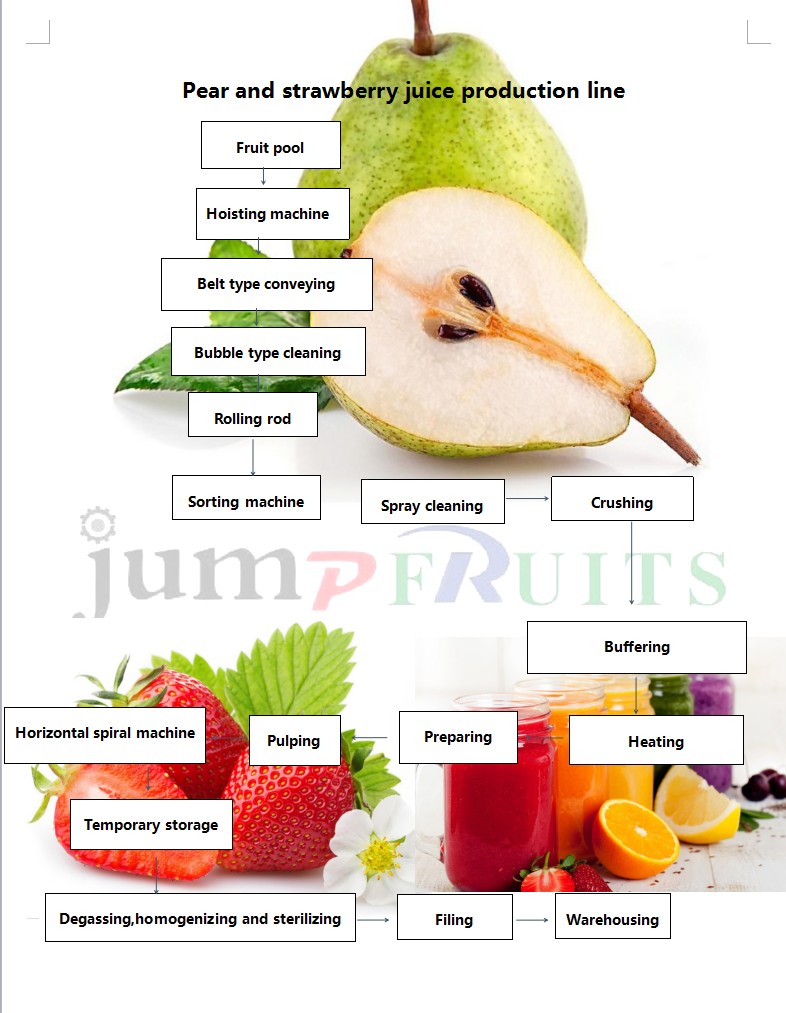

Mohala oa tlhahiso ea lero la litholoana

Melemo ea rona:

1.Turnkey tharollo.Ha ho hlokahale hore u tšoenyehe haeba u tseba ho fokolang ka mokhoa oa ho etsa semela naheng ea heno. Ha re u fe thepa feela, empa hape re fana ka lits'ebeletso tsa sebaka se le seng,ho tsoa moralong oa hau oa polokelo (metsi, motlakase, basebetsi), koetliso ea basebetsi, ho kenya mochini le ho lokisa liphoso, ts'ebeletso ea bophelo bohle kamora ho rekisa jj.

Phihlelo ea lilemo tse 2.15 ea kantle ho naha, tsamaisa thepa habonolo monyako oa hau

Ts'ebeletso ea 3.customized, re tla leka ka hohle ho finyella tlhokahalo ea hau.

4.Tiisetso ea boleng: Likhoeli tsa 12.Kamora moo, lienjineri le tsona lia fumaneha ka litšenyehelo tsa hau tsa ho tsamaea le likarolo tse ling. Re fana ka ts'ebeletso ea bophelo bohle kamora ho rekisa.

Melemo ea mantlha ea mohala oa rona oa sistimi:

1. Lebelo le phahameng la tlhahiso le fihletsoeng ke tsamaiso ea hlooho e sa tsoa etsoa (hlooho e le 'ngoe kapa mafahla a fumanehang), ho tšepahala ho ntlafetseng ho tloha ho PLC e laoloang ka ho feletseng mokhoa oa ho itlhahloba.

2. Ho feto-fetoha ho hoholo ka ho kopana le maemo a fapaneng a ho paka ka lihlahisoa tse fapaneng.

3 E hokahana hantle le tube e ka har'a sterilizer ea li-tube, haeba ho na le ho se sebetse hantle ka sehlahiswa, sehlahisoa se tla its'etleha ho khutlela ka tankeng ea buffer pele ho sterilizer ea UHT.

4. Tšebeliso ea mokotla o se nang letho o tiisitsoeng ka hermetically o tiisa hore mokotla o tla lula o se na letho pele o tlatsoa.

5. Mouoane o nang le khatello e phahameng ea khatello o sebelisoa bakeng sa sterilization ea ho kenngoa, cap le karolo e pepesitsoeng ea filler pele ho potoloho e 'ngoe le e' ngoe ea ho tlatsa.HA HO KHEMIKALI e batloang.

6. Ho tiisoa ha valve ea ho tlatsa ka hare ho setsi ho boloka sehlahisoa se le hōle ka ho feletseng le sebaka sa ho tiisa sephutheloana.

7. Ho tiisoa ha mocheso oa hermetic ho fana ka mokhoa o hlakileng oa ho koala le ho thibela oksijene e phahameng.

8. Kakaretso ea aseptic moralo oa ho tlatsa o lumella ho se sitisoe.Ts'ebetso ho pholletsa le sehla sa tamati / litholoana, ho eketsa katleho ea semela sa hau

9. CIP le SIP li fumaneha hammoho le tube in tube sterilizer

Amohela potso efe kapa efe!Tel/Wechat/Whatsapp:008613681836263

Setsi sa ho etsa lero la litholoana ka boiketsetso

1.Mohala oohle o iketselitse

2.Seta ho hlatsoa, ho tlatsa le ho kenya mesebetsi e meraro 'meleng o le mong

3.e loketse bakeng sa lero la botlolo la PET le mocheso o phahameng o hanyetsanang le ho tlatsa seno sa tee

4.e entsoe ka boleng bo phahameng ba tšepe ea SUS304stainless

5.applying touch screen bakeng sa tshebetso

Mohala oa tlhahiso ea lero la litholoana o entsoe ka motsoako oa phofo oa metsi, filthara ea sirapo, filthara ea duplex, vacuum degasser, UHT sterilizer le homogenizer, joalo-joalo.Lintho tse tala e ka ba litholoana tse foreshe kapa lero le tekiloeng.E ka sebelisoa ho etsa mohala oa tlhahiso ea lero la lamunu, mohala oa tlhahiso ea lero la apole, mohala oa tlhahiso ea lero la perekisi, le mohala oa tlhahiso ea lero la cherry joalo-joalo Re ka boela ra qapa melapo ea tlhahiso ea tloaelo ho latela litlhoko tsa bareki.

Mokhoa oa tlhahiso:

I: khetho ea lisebelisoa tse tala

Khetha tatso e butsoitseng ka botlalo, e ncha, e ntle le lero le nang le lero le lengata, ha ho na mafu a limela le likokoanyana tse senyang tsa TaoGuo, kholo e sa lekaneng ea TaoGuo e lokela ho feta kamora ho pheha.

II: pheko ea thepa e tala

1.clean.Lisebelisuoa tse tala li khethoa ka mor'a hore li hloekisoe ka metsi a hlakileng a hlatsoe le borashe ho MAO net ka 1% hydrochloric acid solution kapa detergent solution hape ka mor'a ho hlatsoa, ho tlosa masala a chefo e bolaeang likokoanyana, ebe o hlatsoa ka metsi a hloekileng, a tšolle hantle.

2.khaola halofo ho ea nuclear.Cheka mochini oa nuclear o khaotsoe ka halofo.

3.soak sireletsa mmala.Seha ka mor'a hore ho cheka lisebelisoa tsa nyutlelie ka 0.1%.Motsoako oa ascorbic acid le citric acid solution soak sireletsa mmala.

III: ho otla ha mocheso

Litholoana sengoathoana tlas'a 90 ° C ho 95 ° C, mocheso bakeng sa 3 ho metsotso e 5, ho nolofatsa, ho otla ka pore boholo ba 0.5 limilimithara beater, tlosa letlalo.

IV: ho fetola tatso

Ka mor'a ho sebetsana le bokaholimo ba makhasi a litholoana e le ho eketsa tatso ho lokisoa.Eketsa tsoekere, citric acid le L - ascorbic acid le metsoako e meng.Its ratio ea perekisi pulp 100 kg, 80 kg 27% solution ea tsoekere, citric acid. , L - ascorbic acid 0,07 0.45 lik'hilograma - 0,2 lik'hilograma.

V: ho tlosoa ho homogeneous

Homogeneous ke ho etsa lero makhasi a likaroloana emisitswe e arotsoe ka likaroloana tse nyenyane le ka mokhoa o ts'oanang a qhalakantsoeng ka lero la litholoana, ho eketsa botsitso ba lero la litholoana, ho thibela stratification.

1.Homogeneous mokhoa ke ho mahoashe filtara lero ka khatello e phahameng homogenizer, ho etsa lero ka makhasi a likaroloana le colloid lintho tse bonahalang ka khatello e phahameng ka 0.002 0.003 limilimithara bophara ba masoba le ho ba likaroloana tse ntle ho feta.Hangata sebelisoa ka tlhahiso ea 130-160 lik'hilograma. /cm2 homogenizer.E boetse e ka sebelisoa bakeng sa homogeneous colloid leloala.Ha lero ka lekhalo colloid leloala la 0.05 0.075 limilimithara petsoha, ka litholoana pulp granules ka matla centrifugal matla a sebetsa le ho kopanetsoe tshusumetso, ka tsela eo finyella homogeneous.Ha lero la litholoana ka har'a oksijene, naetrojene le carbon dioxide le likhase tse ling, har'a bona, naetrojene e ka etsa hore vithamine C le lintho tse pigment tse kang oxidation le corrosion ea makotikoti tinplate, ka hona, e lokela ho ba degassing, degassing mokhoa ha e le hantle o na le mefuta e 'meli e latelang: vacuum method.Lero le kenang ka har'a sets'oants'o sa vacuum le etsa lero ka jet ea micro mist le degassing. Ho nkuoa ka mokhoa oa vacuum ea degree ea vacuum ke 685-711 mm hg kapa ka holimo, mocheso o ka tlase ho 43 °C.

2.Naetrojene phapanyetsano mokhoa.Juice ho tloha thipa khalase tube kapa stainless steel tube cone top ho kena khatello ea nitrogen ho tloha tlase.Nitrogen ka mor'a ho kopanya li-bubble tse nyenyane tse entsoeng ka lero la litholoana, li ile tsa nkela oksijene ka lero la litholoana sebaka le ho finyella sepheo. ea degassing.

VI: tanka ea ho thibela likokoana-hloko

Lero le futhumatsoa ho 95 ° C.E nka 1 min, seteraeke se ka etsahala hang-hang.

VII: ho pholisa ho tiisitsoeng

Sekoa sekoahelo sa botlolo, tanka e sothehile ka motsotso o le mong. Hang ka mor'a hore tiiso e arole pholile ho 38 ° C kapa ho feta, 'me e ntan'o boloka polokelo ea thepa. Lihlahisoa tsa tee tsa litholoana tse tšoanelehang li pinki kapa li sootho, li lumelletsoe bofubelu bo lefifi; SAP uniform opacity, Ka mor'a hore likaroloana tsa phomolo ea nako e telele li fokotsehe; Ka tatso ea lero la perekisi, ntle le monko o ikhethang; Soluble solids e ne e le 10% - 14%

1.Boemo: 1000-30000bph

2.Botlolo ea boholo: 250-1500ml

3.Amohela moralo o khethehileng

4.CE ISO e amohetsoe

Kenyelletso ea mohala oa tlhahiso ea PET / khalase ea lamunu / mango

1) Mochini o sebelisoa haholo ts'ebetsong ea ho tlatsa lino.Mesebetsi e meraro ea ho hlatsoa libotlolo, ho tlatsa le ho tiisa li entsoe ka 'mele o le mong oa mochine.Ts'ebetso eohle e iketselitse.Mochini o sebelisetsoa ho tlatsa lero, metsi a liminerale le metsi a hloekisitsoeng ka libotlolong tse entsoeng ka polyester le polasetiki.

2) Mochini o ka boela oa sebelisoa ho tlatsa mocheso haeba o kentsoe ka sesebelisoa se laolang mocheso.Mochine oa mochine o ka fetoha ka bolokolohi le ka mokhoa o bonolo ho fetola mochine ho tlatsa mefuta e sa tšoaneng ea libotlolo.

3) Ts'ebetso ea ho tlatsa e potlakile ebile e tsitsitse haholoanyane hobane ts'ebetso ea ho tlatsa khatello e nyane ea mofuta o mocha e amoheloa.Moo tlhahiso le molemo oa mochine o phahametse mechine ea litlhaloso tse tšoanang.The OMRON programmed controller (PLC) e tsoetseng pele e amoheloa ho laola mochine hore o sebetse ka bohona ha transducer e sebelisoa ka liketane tse kenang ka botlolong ho fetola lebelo le ho hokahanngoa le transducer ea mochine o moholo ho etsa hore ts'ebetso ea ho tsamaisa botlolo e tsoele pele ka mokhoa o tsitsitseng le ka botshepehi.

4) Ho bonolo ho sebetsa ka othomathike e phahameng hobane karolo e 'ngoe le e' ngoe ea mochini e hlahlojoa hore e tsamaise motlakase oa lifoto, Litabeng, likarolo tsa ho tlatsa mochini li ka fetoloa mekhoa ea ho tlatsa ea vacuum e tlase.

5) Mokhahlelo oa ho tlatsa oa vacuum e tlase (mochini oa mofuta oa Z) o sebetsa ka libotlolong tsa khalase, ho tlatsa joala, soya le lisebelisoa tse joalo.Sekoahelo sa bosholu ba aluminium le kepisi ea polasetiki li ka amoheloa.Mochine ke sesebelisoa se ratoang haholo ke baetsi ba lino.

Litšobotsi tsa mohala oa tlhahiso ea PET / khalase ea lamunu / mango

1. Ho sebelisa moea o ile a romela ho fihlella le ho tsamaisa lebili ka botlolo ka ho toba amahanngoa thekenoloji;Sekoti se hlakotsoeng le liketane tsa conveyor, sena se nolofalletsa phetoho ea sebopeho sa botlolo hore e be bonolo.

2. Phetiso ea libotlolo e amohela theknoloji ea "clip bottleneck", phetoho e bōpehileng joaloka botlolo ha e hloke ho fetola boemo ba lisebelisoa, ho lekane feela ho fetola poleiti e kobehileng, lebili le likarolo tsa nylon.

3. Sekotwana sa mochini o hlatsoang libotlolo tsa tšepe tse entsoeng ka mokhoa o khethehileng se tiile ebile se tšoarella, ha se na ho ama sebaka sa screw sa molomo oa botlolo ho qoba tšilafalo ea bobeli.

4. Lebelo le phahameng la lebelo le leholo la matla a khoheli a phallo ea li-valve, ho tlatsa ka potlako, ho tlatsa ho nepahala le ho se lahleheloe ke metsi.

5. Spiraling e fokotseha ha botlolo e hlahisoang, fetola sebopeho sa botlolo ha ho hlokahale hore u fetole bolelele ba liketane tsa conveyor.

6. Host e amohela theknoloji e tsoetseng pele ea ho laola PLC, lisebelisoa tsa motlakase tsa bohlokoa tse tsoang k'hamphaning e tummeng e kang Mitsubishi ea Japane, France Schneider, OMRON.

Tšebeletso ea pele ho thekiso

Re ka fana ka maikutlo a moreki mochine o loketseng ka ho fetisisa ho latela foromo ea bona le thepa e tala."Moqapi le nts'etsopele", "tlhahiso", "ho kenya le ho laela", "thupelo ea theknoloji" le "ka mor'a tšebeletso ea thekiso".Re ka u tsebisa morekisi oa thepa e tala, libotlolo, lileibole joalo-joalo. Rea u amohela kopanong ea rona ea tlhahiso ho ithuta hore na moenjiniere oa rona o hlahisa joang.Re ka etsa mochini ho latela tlhoko ea hau ea 'nete, 'me re ka romella moenjiniere oa rona fekthering ea hau ho kenya mechini le ho koetlisa mosebeletsi oa hau oa Ts'ebetso le tlhokomelo.Likopo tse ling hape.Feela re tsebise.

Tšebeletso ea ka mor'a thekiso

1.Ho kenya le ho laela: Re tla romela basebetsi ba nang le phihlelo le botekgeniki ho ba le boikarabelo ba ho kenya le ho laela thepa ho fihlela thepa e tšoaneleha ho netefatsa hore thepa e nakong le ho kenngoa tlhahisong;

2.Ho etela khafetsa: Ho netefatsa ts'ebetso e tsitsitseng ea nako e telele ea lisebelisoa, re tla ipapisa le litlhoko tsa bareki, re fane ka makhetlo a le mong ho isa ho a mararo ka selemo ho tla tšehetso ea theknoloji le litšebeletso tse ling tse kopanetsoeng;

3.Tlaleho e qaqileng ea tlhahlobo: Ebang ke ts'ebeletso ea kamehla ea tlhahlobo, kapa tlhokomelo ea selemo le selemo, baenjiniere ba rona ba tla fana ka tlaleho e qaqileng ea tlhahlobo bakeng sa moreki le polokelo ea polokelo ea litšupiso tsa k'hamphani, molemong oa ho ithuta ts'ebetso ea lisebelisoa neng kapa neng;

4.Fully feletseng likarolo inventory: E le ho fokotsa litšenyehelo tsa likarolo inventory hao, fana ka tšebeletso molemo le ka potlako ho, re lokiselitse lethathamo le feletseng la likarolo tsa thepa, ho kopana le bareki khoneha nako ea ho batla kapa tlhokahalo;

5. Koetliso ea litsebi le tsa tekheniki: E le ho etsa bonnete ba hore ts'ebetso ea basebetsi ba tekheniki ea bareki ba tloaelane le lisebelisoa, ho utloisisa ka nepo ts'ebetso ea lisebelisoa le mekhoa ea tlhokomelo, ntle le ho kenya koetliso ea tekheniki sebakeng sa marang-rang.Ntle le moo, o ka ts'oara litsebi tsa mefuta eohle ho lithupelo tsa feme, ho u thusa ho utloisisa theknoloji ka potlako le ka botlalo;

6.Software le lits'ebeletso tsa boeletsi:E le ho lumella basebetsi ba hau ba tekheniki ho ba le kutloisiso e kholo ea tlhabollo e amanang le lisebelisoa, ke tla hlophisa ho romella thepa khafetsa ho makasine ea boeletsi le tlhaiso-leseling ea morao-rao. Ha ho hlokahale hore u tšoenyehe haeba u tseba hanyane ka mokhoa oa ho etsa semela naheng ea heno. Ha re fane ka lisebelisoa ho uena feela, empa hape re fana ka ts'ebeletso ea sebaka se le seng, ho tloha moralong oa hau oa polokelo (metsi, motlakase, mouoane), koetliso ea basebetsi, ho kenya mochini le ho lokisa liphoso, bophelo bohle. tšebeletso ea ka mor'a thekiso joalo-joalo.