Tin can tamati peista litholoana juicer tlhahiso ea mochini mochini

- Nomoro ea Mohlala:

-

mooketsi

- Lebitso cha:

-

SH-QHOBELA

- Sebaka sa Tšimoloho:

-

Shanghai, Chaena

- Palo ea li-volts:

-

380V

- Matla:

-

4kw

- Teba (L * W * H):

-

1100 * 265 * 920mm

- Boima:

-

100T

- Bopaki:

-

CE ISO

- Waranti:

-

Likhoeli tse 12

- Ka mor'a-thekiso Tšebeletso Ka:

-

Baenjiniere ba fumaneha bakeng sa lits'ebeletso tsa ts'ebeletso mose ho maoatle

- Boemo:

-

E ncha

- Mofuta:

-

retelehela senotlolo sebetsa mola

- Lebitso sehlahisoa:

-

litholoana juicer tlhahiso ea mochini

- Production bokgoni:

-

0.5-500T / H

- Bokgoni:

-

1-5t / h

- Lintho tse bonahalang:

-

SUS304

- Lisebelisoa tse so ntlafatsoe:

-

Litholoana tse ncha

- Melemo:

-

Nako e telele ka mor'a-thekiso Service

- Kopo:

-

Mohala oa ho lokisa litholoana

- Mala:

-

Litlhoko tsa Bareki

- Mosebetsi:

-

jusi

- Tšebeliso:

-

ho etsa lero

- 8 Behantsha / Sets ka Khoeli le Khoeli litholoana juicer tlhahiso ea mochini mochini

- Lintlha tsa ho paka

- sephutheloana se tloaelehileng sa kantle ho naha, se phuthetsoe ka filimi ea polasetiki le ka lehong

- Boema-kepe

- Shanghai

- Lead Time :

- Matsatsi a 60-90

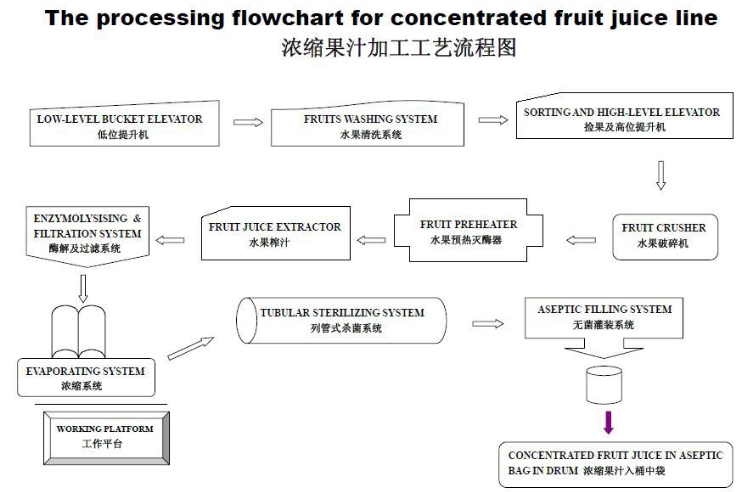

2.The kaofela mola sebopeho:

A: Sisteme ea ntlafatso ea litholoana tsa mantlha, sistimi ea ho hloekisa, sistimi e sithabetsang, sisteme ea ho futhumatsa pele ho futhumatsa, sistimi ea pulping, sistimi ea mahloriso

B: pompo → ho kopanya moqomo → homogenization → ho theola moea → mochini o nyopisang → mochini o hlatsoang → Mochini o tlatsang → mochini o tlamang → mochini o nyanyatsang oa kotopo → seomisi → ho kh'outa → litebele

Spray mochini o hloekisang

Main bath:

E sebelisetsoa ho hlatsoa tamati e ncha, fragola, mango, jj.

Moralo o ikhethileng oa ho palama maqhubu le ho phatloha ho netefatsa ho hloekisa le ho fokotsa tšenyo ea litholoana hape.

3 E loketse mefuta e mengata ea litholoana kapa meroho, joalo ka tamati, fragola, apole, limango, jj.

Motlakase oa Motlakase: 3KW

homogenizer

E sebelisoa ho ntlafatsa kapa ho emulsification ea lero, jeme, seno.

Le taolo maqhubu a ho sokoloha le raka gare wa taolo raka

Rated tshwara bokgoni 1T / H.

Sistimi e hloekileng ea CIP

Semi-jarolla ka ho iketsa tsamaiso e khopo ho hloekisa

Ho kenyelletsa tanka ea asiti, tanka ea motheo, tanka ea metsi a chesang, sistimi ea phapanyetsano ea mocheso le litsamaiso tsa taolo. Ho hloekisa mohala kaofela.

Matla: 7.5KW

Setsi sa Citrus

Main bath:

1. Kaho ea tšepe e sa hloekang libakeng tsohle tseo ho ka ikopanngoang le tsona, moaho oa tšepe o koetsoeng ka ho felletseng libakeng tsohle tseo ho ka ikopanngoang le tsona, sistimi e kenngoeng ka ho phethahala ea liphaephe tsa tšepe ho tsamaisa lero ho ba phethellang ka tšepe.

2. Sisteme ea ho ntša lilamunu e ikhethile ka hore ka nako e ts'oanang e folisa oli hammoho le lero nakong ea potoloho e tšoanang.

3. Likarolo tse bohloko tse kang li-cores, lera, lipeo, jj. Li arohanngoa hang-hang le lisele tsa lero le lero ka "tube" ea pre-finisher nakong ea potoloho ea ho ntša metsi.

4. Ts'ebetso ena e ikhethang e entsoe hore e khonehe ka lebaka la bokhoni ba Moqapi oa Citrus ho pepeta litholoana tsa citrus hantle ka boholo le sebopeho.

5. Tšoara boholo ba mefuta ea lilamunu le boholo ba eona. Sena se fokotsa palo ea ba ntšang lintho tse hlokoang, ho fella ka ho boloka sebaka le ho fokotsa litšenyehelo tsa lisebelisoa.

6. Ts'ebeliso ea metsi le ho lahla litšila li fokotsoa ka ts'ebeliso ea litsamaiso tse sebelisang metsi hape.

Khetha bracket e sa hloekeng, polasetiki ea lijo le polasetiki e thata kapa sesebelisoa se sa hloekang, ho rala meralo ea lehare ho thibela jeme ea litholoana; Sebelisa importing dibering-ba khahlanong le ts'enyeho, habeli sekamela lehlakoreng le le tiiso; ka makoloi a fetisang a fetohang a sa khaotseng, maqhubu a fapaneng a lebelo le litšenyehelo tse tlase tsa ts'ebetsoTitle e ea mona.

Stainless roller roller conveyor, chenchana le tharollo, mofuta o felletseng oa cheke, ha ho hlokahale. Sethala sa litholoana se entsoeng ka matsoho, pente e khabisitsoeng ka khabone ea tšepe, tšepe e sa hloekeng ea antiskid, terata ea tšepe e sa hloekang.

C. Crusher

Fusing thekenoloji Setaliana, lihlopha tse ngata tsa sebopeho sefapano lehare, bee boholo ka fetola ho ea ka moreki kapa ditlhoko tsa porojeke e itseng, e tla eketsa sekhahla lero lero la 2-3% a lekanyelitsoeng le sebopeho ea moetlo, e leng a loketse bakeng sa tlhahiso ea onion spaghetti, sopho ea rantipole, sopho ea pepere, sopho ea apole le litholoana tse ling le sopho ea meroho le lihlahisoa

D. Mochini o hulang habeli oa sethala

E na le mochini o koahetsoeng 'me lekhalo le nang le mojaro le ka fetoloa, taolo ea maqhubu, e le hore lero le hloeke; Ho buloa ha letlooeng ka hare ho ipapisitse le litlhoko tsa projeke tse itseng ho odara

E. Evaporator

Phello e le 'ngoe, phello e habeli, phello ea makhetlo a mararo le evaporator e mengata, e tla boloka matla a mangata; Tlas'a lephaka, ho futhumala ha potoloho e tlase ea mocheso ho matlafatsa ts'ireletso ea limatlafatsi 'meleng le ho tsa pele. Ho na le sistimi ea ho hlaphoheloa mouoane le sistimi ea condensate makhetlo a mabeli, e ka fokotsa ts'ebeliso ea mouoane;

F. Mochini o nyopisang

Ha u se u fumane theknoloji e robong e nang le tokelo ea molao, nka melemo e felletseng ea phapanyetsano ea mocheso oa thepa ho boloka matla- e ka bang 40%

F. Mochini o tlatsang

Amohela theknoloji ea Italy, lihloohoana le lihlooho tse peli, ho tlatsa ho tsoelang pele, ho fokotsa ho khutla; U sebelisa ente ea mouoane ho itšepa, ho etsa bonnete ba hore u tlatsa boemo ba aseptic, sethala sa bophelo ba sehlahisoa se tla senya lilemo mochesong oa kamore; Ha o ntse o tlatsa, o sebelisa mokhoa oa ho phahamisa o khabisang ho qoba tšilafalo ea bobeli.

Likarolo tsa lihlahisoa

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu