Kenyelletso ea mokhoa oa tlhahiso

Ts'ebetso ena ea tlhahiso e sebelisa sekoahelo sa mochini ho fepa.Ha e na litlhoko tsa lisebelisoa tse tala tsa sludge (ha ho na litšila≥5CM).E bonolo ebile e loketse, e boloka mosebetsi le nako, e fokotsa litšenyehelo ebile e ntlafatsa ts'ebetso.

1. Ho fepa: (silo e kentsoeng ka botlalo e setiloe)

Ka mor'a hore lisebelisoa li fepeloe ka har'a silo ka lifti, qala valve ea ho fepa le ea ho fepa, 'me ka mokhoa o ts'oanang u kene ka har'a auger kapa hydraulic feeder ho ea ka maemo a behiloeng,' me u sebelise sefepi ho fepa lisebelisoa ka ketlele e phunyehang.

2. Pyrolysis

Ho phatloha, ho beha mocheso oa 350℃- 470℃.Lebelo la ho potoloha ha ketlele e petsohang ke metsotsoana e 150 ka selikalikoe.Ka mor'a ho phethoa ha ho phunyeha ha seretse sa oli, se setseng se kena ka har'a mochine oa slag, o romelang masala ka har'a metsi a pholileng a slag.Masala a kenngoa ka mokotleng oa lithane ho tloha mocheso o phahameng ho ea mocheso o tloaelehileng 'me a phuthetsoe bakeng sa polokelo ea nakoana.

3. Ho futhumatsa, ho laola khatello

Ho sebelisoa khase ea mafura e bolokang tikoloho haholoanyane bakeng sa ho futhumatsa.Ho phunyeha ha mocheso o phahameng ho na le lienjine tse 'nè tsa mafura a 30w le lithunya tse' nè tsa ho fafatsa khase, tseo kaofela li laoloang ka bohlale ho netefatsa mocheso o tloaelehileng o hlokahalang bakeng sa tlhahiso ea ho phunyeha.

Khatello ea tlhahiso ea tlhahiso ea thepa e tloaelehile, khatello e tloaelehileng ea tlhahiso ke 0.01MPa - -0.02MPa, 'me khatello e phahameng e behiloeng ke 0.03MPa.Nakong ea ts'ebetso ea tlhahiso, sensor ea khatello ea khatello e fana ka letšoao la ho utloa khatello.Mokhoa oa ho laola khatello o bula kapa o koala valve ea ho laola khatello ho latela khatello e behiloeng, 'me e romela khopotso ea alamo ho netefatsa tlhahiso e sireletsehileng ea thepa.

3.4 Ts'ebetso ea tlhahiso

Pele ho tlhahiso, hlahloba hore na sesebelisoa sa ho khanna motlakase se tloaelehile, ho kenyelletsa le (circuit, reducer, blower, induced draft fan, circulating water pump), hore na winch ea ho fepa le winch ea ho ntša e sebetsa ka mokhoa o tloaelehileng, le hore na khabinete e bohlale ea kabo ea matla e na le phoso. (ikopanye le basebetsi ba tlhokomelo pele o hloleha, 'me u se ke oa e qala ka kotloloho)

Mokhahlelo oa ho fepa

Mokhahlelo oa tlhahiso: pele ho tlhahiso, hlahloba hore na enjene ea mafura, pompo ea moea, compressor ea moea le blower li tloaelehile, hlahloba hore na tiiso ea metsi e haelloa ke metsi, boloka valve ea moea ea winch e bulehile, boloka valve ea slag e koetsoe, le boloka belofo ea moea ea moqomo oa mouoane e bulehile, ebe u etsa hore sebōpi se potolohe ho ea pele ka metsotsoana e ka bang 100 / selikalikoe ka ts'ebetso ea khabinete e bohlale ea kabo ea matla.Ha enjene ea mafura e buloa ho phahamisa mocheso ka 50℃, koala valve ea moea ea mochine oa khase, Butle-butle phahamisa mocheso ho 150℃- 240℃, 'me khase e sa tsitsang e qala ho hlahisoa.E romeloa sebōping sa mollo bakeng sa ho tuka ka mokhoa oa ho khutlisa khase ea mafura.Ho latela palo ea khase e sa koaheleheng, tima palo ea lienjine tsa mafura ho boloka boemo ba mollo o liehang.(Haeba palo ea khase e sa koaheloeng e le khōlō, e tla romelloa ho sehlopha se seng sa thepa bakeng sa ho tuka ka li-valve tsa letsoho. Haeba lisebelisoa tse ling li sa e hloke, khase e feteletseng e sa fokotseheng e ka romelloa kamoreng ea bobeli ea ho tuka), le ebe butle nyolohela ho 380-450℃.Netefatsa hore petso e hloekile.Ho fokotseha ha khase e sa koahelehang,

Sistimi ea ho hloekisa naetrojene;E sebelisoa haholo-holo ho hloekisa ketlele, se amohelang khase, sekontiri, se arolang khase ea oli le moqomo oa slag o pholileng ka metsi ho nkela khase e sa koalehang sebaka ka naetrojene.Netefatsa polokeho ea tlhahiso ea lisebelisoa.

Sistimi ea slagging;Pele ho ts'oaroa ha slag, valve ea moea e tsoang ka har'a cage ea winch e tla koaloa ka khabinete ea motlakase e bohlale, sistimi ea ho pholisa molora e tla buloa bakeng sa phetisetso, 'me pompo ea metsi e potolohang e tla buloa.Ha valve e boima ea oli e buloa, oli e nyenyane ea oli e boima e tlameha ho ntšoa pele ho qoba ho khomarela lesaka la ho ntša slag.Koala valve e boima ea oli ka mor'a hore oli e boima e tšolloe.'Mele oa sebōpi o khutlela morao' me o qala ho ntša slag bakeng sa lihora tse 1-1.5.

Lintho tse bonahalang tsa kettle e phunyehang: 316L tšepe e sa hloekang Q245RQ345R naha e tloaelehileng ea boiler tšepe poleiti

Boholo ba kettle ea pyrolysis:φ 2800MM*7700MM

Sebaka sa phapanyetsano ea molumo le mocheso oa ketlele e petsohang: 47m3 le 80m2

Mokhoa oa condensation le sebaka sa phapanyetsano ea mocheso: ho futhumatsa metsi 90m2

Sebopeho sa sebopeho se ka sehloohong: ho potoloha ka holimo

Khatello ea tsamaiso: khatello e tloaelehileng

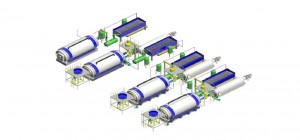

Sebaka sa lisebelisoa: bolelele ba 50m, bophara ba 10m le bophahamo ba 6m

Thepa boima: 50-60t

Ts'ebetso ea bopaki ba ho phatloha: lisebelisoa tsohle tsa motlakase li na le lisebelisoa tsa motlakase tsa naha tsa YB tse sa phatloheng.

Tšebeliso ea mafura: 600 m ea khase ea tlhaho e sebelisoa ka letsatsi bakeng sa mofuta o tsoelang pele³/ D e hloka 500L/D ea oli ea mafura

Sistimi ea matla le kabo: lisebelisoa li na le matla a felletseng a 46.4 kilowatts.

Khabinete e le 'ngoe e bohlale ea taolo ea komporo e na le lisebelisoa (taolo ea matla, mocheso, alamo ea ponts'o ea dijithale, ts'ebetso e bohlale ea li-valve le mesebetsi e meng).

Karolelano ea matla ka hora ke 30kw, 'me kabo ea letsatsi le letsatsi e ka ba lihora tse 500-600 tsa kilowatt..

Nako ea poso: Jan-09-2023